Improved project estimates.

Accurate estimates allow midstream companies to make investment decisions with full visibility into their consequences, when there’s still time to set clear expectations for expected rates of return or to deploy capital in more productive avenues. But when estimates are too low, the possibility of cost overruns remains hidden until significant amounts of capital have already been sunk into the initial phases of a project.

In this piece, we outline 4 ways to leverage data to achieve a more fact-based, consistent, and most importantly, accurate, approach to estimating project costs.

Our energy experts recommend 4 ways to begin improving your estimates today:

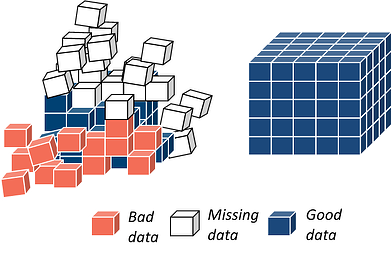

1. Invest in cleaning internal project data

No project-based company can succeed without knowing where it’s spending its money. Access to clean historical cost data is the foundation for estimates that reflect the real, on-the-ground costs of past projects.

To begin the data cleansing process, midstream companies should take the following first steps:

- Extract internal project data from all sources (ERP accounting information, WBS categorizations, P-Card systems)

- Centralize project data into a database accessible to all stakeholders

- Assign all spend data to unique projects, being sure to isolate sub-components of larger projects (e.g., compressor stations and pipelines within a larger project)

- Re-categorize costs that have been miscategorized at the invoice level

- Scrub project data for unrelated costs, such as accounting reconciliations, partner payments, and unrelated scope

Additionally, a team of estimators should be trained to apply newly actionable historical data to future projects in a consistent and standardized way. Estimation teams must have the skills to:

- Make assumptions about the cost categories that will drive future projects, in terms of the categories used to bucket historical spend

- Make assumptions about costs that will fall into each category for future projects, on the basis of historical cost data

- Calculate risk and certainty factors

The goal of developing an internal project database is to turn estimation processes from cost centers into return-generating internal knowledge assets that strengthen as the company portfolio evolves.

Interested in learning how to develop better project data? Email us to set up a free consultation.

2. Develop market insight assets

Strategic midstream companies possess a central repository of market information that all estimators can draw from, instead of relying on idiosyncratic approaches to data gathering. Those repositories should include:

- Up-to-date market cost information for key project components

- Indices that measure changes in the key commodities that drive project costs

- Publicly available project data on competitors' actual project costs, gathered from government entities like FERC

- Standardized, company-wide forecasts for key project categories, based on qualitative and quantitative market data gathered from publicly available data and market research

- Risk factors that quantify commodity exposure for each project category

The challenge is as much about data collection as it is about standardization -- in our experience, the most successful estimating teams establish sets of Standard Operating Procedures that define the foundational assumptions to be used in every estimate, and they refresh those assumptions on a regular (biweekly or monthly) basis in team meetings.

Interested in learning how to improve your external market insights? Email us to talk about how.

3. Conduct statistical analysis on project cost drivers

|

In order to evaluate the profitability of future projects, midstream companies must understand, in detail, exactly what costs will drive them. Because historical projects often differ significantly from one another, you should invest in developing the tools to compare them along the same baseline, accounting for the unique, project-specific variables of each.

That means being able to quantify the rockiness, affluence, and soil type of each project (among other variables) as well as the extent to which those variables changed each historical project’s cost and are expected to change the costs of future projects. To do that, midstream companies should develop the following capabilities:

- Interview key project stakeholders to identify the unique costs that drove each historical project

- Distill findings into a standardized dossier of qualitative cost variables. Decide on standard categories within those variables by which to categorize each project (ex: A population density variable with rural, suburban, and urban categories).

- Assign standard categorizations to all historical projects (ex: Project 1 is Rural, Project 2 is Suburban, Project 3 is Urban)

- Assign weights to each category in order to establish a standard process for assessing the extent to which each variable affects cost. Calculate weights by conducting regression analysis on historical project data.

- Combine quantitative and qualitative research into a standard library of cost drivers to be used by all project estimators

- Determine how each new project ranks on each variable. Apply cost driver weights as determined in the standardized library.

- Train all project estimators to implement newly standardized cost driver variables for the projects under their scope

Wondering how to set up a normalization process? Email us to learn more about project cost drivers.

4. Implement a consistent and repeatable process

Centralization under a single party is the foundation of any consistent estimation process. Centralization ensures that all project estimates use the same assumptions, that data work and gathering isn’t duplicated, that internal knowledge evolves as the team learns more, and that there is concrete accountability for estimate outcomes.

There are three ways to develop estimation centralization: (1) Implement an internal task force of Project Managers and Directors in charge of producing all estimates; (2) Hire a team of estimators with the analytical skills and industry experience to work with project data; or (3) Outsource the data cleansing process to a 3rd party.

In addition to centralizing human resources, midstream companies should also begin initiatives to centralize their data resources. That means keeping internal project data and external market data in a central repository accessible by all stakeholders as well as assigning accountability for keeping that data continuously clean and up-to-date.

Do you need help developing one or more of these estimating capabilities?

Sign up to be the first to receive our eBook:

The Comprehensive Guide to Midstream Project Estimation:

How to Improve Your Estimates and Make Profitable Investment Decisions with Data