Our recent posts have shown how declines in steel, fuel, and demand have recently led to millions of dollars in savings opportunities for midstream firms.

Today, we're focusing on 5 immediate opportunities to drive down midstream operating costs.

But with suppliers who have historically been reluctant to pass savings along, midstream firms have to be proactive about negotiating to capture savings.

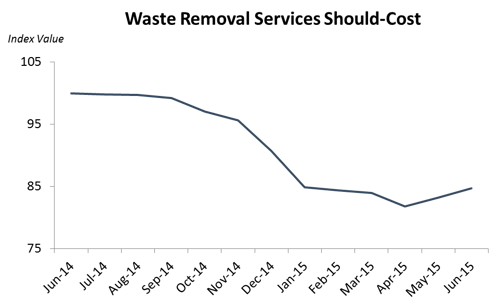

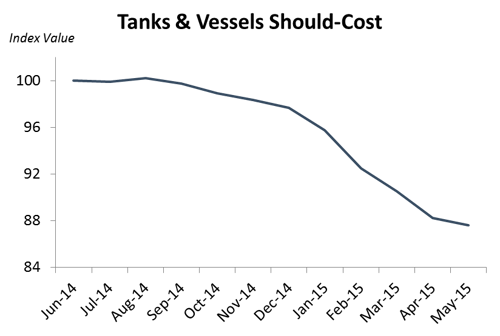

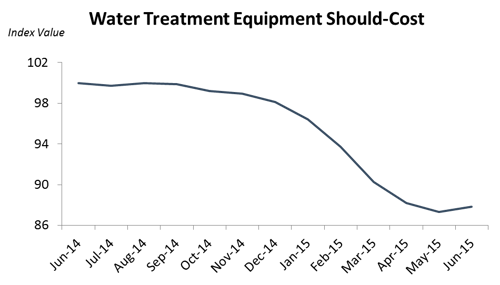

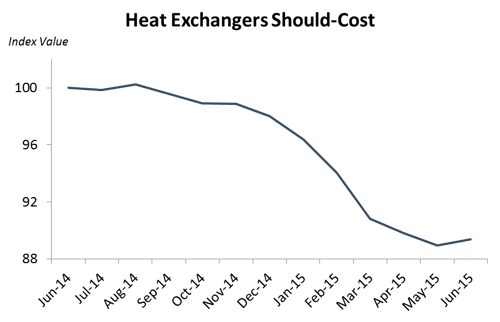

That's why for each of the categories below, we share a "should-cost" model, which quantifies the amount by which each item should have moved over the last year, based on market movements. Our customers regularly use data like this to drive fact-based negotiations with suppliers and ultimately capture savings.

1. Waste Removal Services:

Over the last year, the cost of waste removal services should have declined 15.3%.

2. Tanks and Vessels

Over the last year, the cost of tanks and vessels should have declined 12.4%.

3. Water Treatment Equipment

Over the last year, the cost of water treatment equipment should have declined 12.2%.

4. Heat Exchangers

Over the last year, the cost of heat exchangers should have declined 10.6%

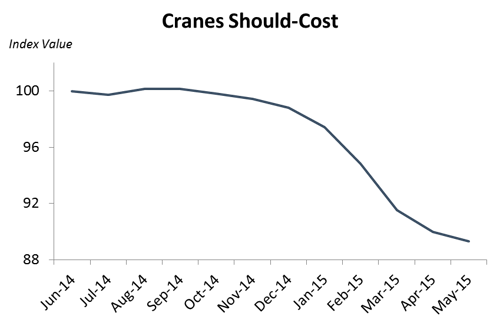

5. Cranes

Over the last year, the cost of cranes should have declined 10.7%

But it's not just these 5 opportunities: midstream costs should have declined across the board. To learn more, read the other posts in our cost reduction series: