Accurate estimates allow midstream companies to make investment decisions with full visibility into their consequences, when there’s still time to set clear expectations for expected rates of return or to deploy capital through more productive avenues. But when estimates are too low, the possibility of cost overruns remains hidden until significant amounts of capital have already been sunk into the initial phases of a project.

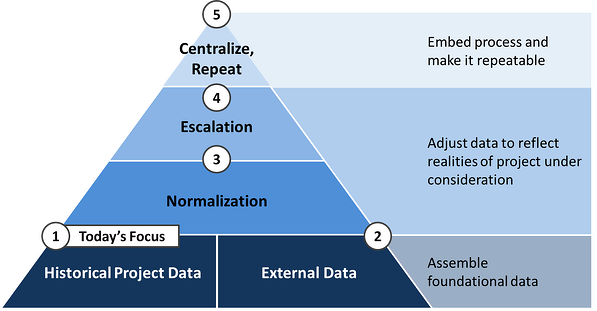

In this piece, we outline how you can begin leveraging your historical project data to achieve a more fact-based, consistent, and accurate approach to estimating project costs. But first, let's introduce the 5 steps that we'll outline in our series on improving estimates:

Simply put, accurate estimates are built on a foundation of accurate and comprehensive data: no technology, new hire, or process improvement can yield accurate estimates without it. This week, we'll focus on the bottom-left hand corner of the pyramid: building analyses on clean and actionable historical data. In the coming weeks, we'll show you strategies to address each and every one of the required estimating capabilities.

Step 1: Invest in cleaning historical project data

No project-based company can succeed without knowing where it’s spending its money. Access to clean historical project cost data is the foundation for producing estimates that reflect the true costs of past projects.

Your internal project data is critical to the estimation process because it provides the most comprehensive and specific project data available to your company. In addition, internal data reflects your unique supply base and sourcing process in a way that no other form of data could.

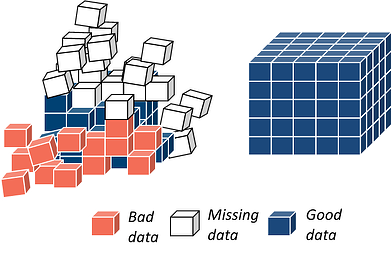

But company-internal project data is too often inaccurate, inaccessible, and miscategorized, leaving project estimators to rely on their personal experience to fill in the gaps. To solve those data problems, midstream companies should invest in aggregating, cleaning, and analyzing past project data:

Aggregating Project Data

To begin standardizing project data, we suggest that midstream companies take the following first steps:

- Extract internal project data from all sources (ERP accounting information, WBS categorizations, P-Card systems, qualitative PM project knowledge) and aggregate it into a single project repository

- Centralize that project data in a database accessible to all stakeholders. Establish version control standards to ensure that only the most up-to-date files are pulled.

- Assign all spend data to unique projects, being sure to isolate sub-components (e.g., compressor stations and pipelines within a larger project)

Cleaning Project Data

Once project data has been extracted and centralized, estimation teams should clean that data to provide an accurate baseline against which to forecast future project costs. That entails the following measures:

- Combing through project data at the invoice and line-item levels in order to recategorize costs that were miscategorized on the front end

- Recategorizing 'miscellaneous' or large bucket costs like 'Services' into more granular categories

- Eliminating errors and duplicates

- Scrubbing project data for unrelated costs, such as accounting reconciliations, partner payments, and unrelated scope

- Checking for common omissions, such as ROW costs

Analyzing Project Data

Additionally, a team of estimators should be trained to apply newly actionable historical data to future projects in a consistent and standardized way. Estimation teams must have the skills to:

- Make assumptions about the cost categories that will drive future projects, in terms of the categories used to bucket historical spend

- Make assumptions about the quantity of costs that will fall into each category for future projects, on the basis of historical cost data and known project requirements

- Network with internal departments to determine project scope, requirements, and risks

- Calculate risk and certainty factors

- Conduct normalization and escalation analyses to make past project data comparable to forecasted projects with differing characteristics

With a well-developed internal project database, midstream companies can turn the estimation process from a cost center into a return-generating internal knowledge asset that will strengthen as the company portfolio evolves. Next week, we'll show you how to make that company-internal project data even stronger by supplementing it with external market information.

Interested in learning about the other steps to more accurate project estimates?

Click here to download our eBook:

The Guide to Midstream Project Estimation

Or read on to the second step of project estimation: external market data.